Choosing the right industrial Epoxy Floor coating can feel like navigating through a maze if you’re not sure what you’re looking for. Fortunately, at Utah Epoxy Coatings, we’ve mastered the art of epoxy coatings and are here to guide you through every step. This ultimate guide is designed to simplify your decision-making Process, ensuring the longevity and resilience of your industrial floors. Whether you’re a seasoned professional or new to the world of epoxy, this comprehensive guide aims to make your selection process as smooth and convenient as possible.

Contents

- 1 Why Industrial Epoxy Coatings?

- 2 The Perfect Fit for Your Facility

- 3 Evaluating Your Environment

- 4 Understanding Different Types of Epoxy Coatings

- 5 Deciding Between Color and Clear Coatings

- 6 Installation Concerns

- 7 Long-Term Maintenance and Care

- 8 Cost Considerations

- 9 Choosing Utah Epoxy Coatings

- 10 Conclusion

Why Industrial Epoxy Coatings?

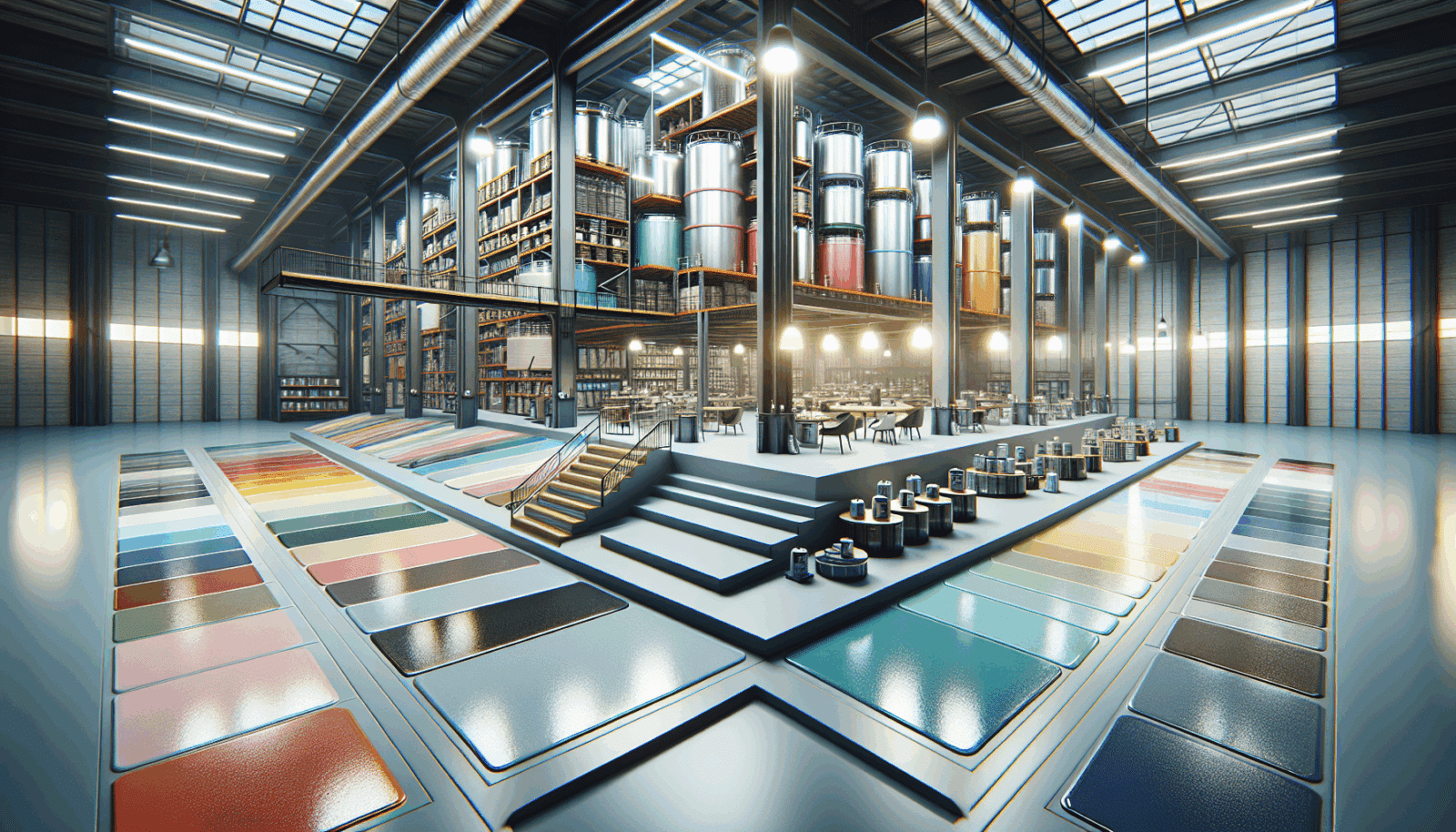

Industrial epoxy floor coatings are more than just a protective layer; they are an investment in your facility’s safety, aesthetics, and overall efficiency. Unlike conventional flooring options, epoxy coatings offer exceptional durability, resisting wear even in high traffic areas. Moreover, their resistance to spills from chemicals, oils, and other substances makes them ideal for maintaining a clean and safe work environment.

Besides their functional benefits, epoxy coated floors can drastically enhance the appearance of your industrial space. Available in various Colors and Finishes, they allow you to customize the look to match your company’s branding or aesthetic preferences, making them a versatile choice for any business.

The Perfect Fit for Your Facility

Finding the right epoxy coating for your facility begins with understanding your specific needs. Consider the nature of your operations – do you deal with heavy machinery, chemicals, or are you in the food and beverage sector? Each scenario demands different properties from an epoxy coating, be it higher chemical resistance, slip resistance, or food safety compliance.

Reflect on your daily operations and traffic. Facilities with heavy foot and vehicle traffic require thicker, more durable coatings that can withstand constant wear without constant repairs or replacements. This initial assessment is crucial in narrowing down your options to those best suited to your environment.

Evaluating Your Environment

The environment within your facility plays a significant role in the type of epoxy coating you select. Temperature fluctuations, for instance, can affect the coating’s curing process and overall performance. Epoxy coatings that are formulated for high-temperature environments ensure that the coating maintains its integrity without peeling or cracking.

Moisture levels in your concrete floors also matter. Some epoxies are specifically designed to combat moisture-related issues, essential in preventing delamination or mold growth. An accurate assessment of your facility’s environmental conditions will guide you in choosing a coating that ensures longevity and durability.

Understanding Different Types of Epoxy Coatings

Epoxy coatings come in various types, each with its unique advantages. Solvent-based epoxies, for example, offer thin, yet very hard-wearing coatings, ideal for industrial settings that demand high durability. However, they often contain volatile organic compounds (VOCs), which can pose health and safety concerns if not handled correctly.

On the other hand, water-based epoxies are more environmentally friendly and easier to apply, making them a popular choice for DIY enthusiasts and facilities that prioritize safety and minimal environmental impact. Understanding these differences is key to selecting the right coating for your project.

Deciding Between Color and Clear Coatings

Choosing between colored or clear epoxy coatings is predominantly a matter of taste and functional requirements. Colored coatings can be used to delineate different areas within your facility, enhance branding, or simply improve the aesthetic appeal of the space. They can also hide imperfections and stains, keeping your floors looking pristine.

Clear coatings, however, celebrate the natural beauty of your existing floors while providing the same level of protection as colored variants. They’re particularly popular in facilities that aim to achieve a modern, minimalistic look. Whichever option you choose, ensure it aligns with your aesthetic preferences and functional needs.

Installation Concerns

Even the highest quality epoxy coating can fail if not properly installed. Preparation is key; the concrete surface must be clean, dry, and properly profiled to ensure the epoxy adheres well and lasts. Hiring professionals with experience in installing industrial epoxy coatings can save you time and money in the long run by avoiding common mistakes that lead to peeling or bubbling.

Moreover, consider the curing time and how it impacts your operations. Some epoxies cure faster than others, allowing you to resume normal operations with minimal downtime. Discuss your timeline and operational needs with your installer to choose a product that fits your schedule.

Long-Term Maintenance and Care

Maintaining your epoxy coated floor is straightforward, but essential for prolonging its life and maintaining its appearance. Regular cleaning with appropriate products is necessary to prevent dirt accumulation and potential staining. Additionally, while epoxy coatings are durable, they can be scratched or damaged by heavy machinery or sharp objects; preventive measures should be taken to avoid such damage.

In areas of high traffic or heavy use, consider implementing maintenance cycles to repair or recoat the epoxy as needed. This proactive approach ensures your floors remain in top condition, safeguarding your investment and maintaining a positive image of your facility.

Cost Considerations

- Material Quality: Higher quality epoxies may come with a higher price tag but offer better durability and longevity, reducing the need for frequent touch-ups or repairs.

- Surface Preparation: Proper surface preparation may involve additional costs, but it is critical for ensuring the epoxy coating adheres well and lasts.

- Installation Expertise: Professional installation ensures that your epoxy flooring is applied correctly, potentially saving you money on future repairs due to improper installation.

- Maintenance Requirements: Some epoxy coatings may require more maintenance than others, influencing your long-term costs.

- Operational Downtime: Consider the curing time of the epoxy and how it aligns with your operations. Coatings that offer quick curing times may be more expensive but allow for minimal disruption to your business.

Choosing Utah Epoxy Coatings

At Utah Epoxy Coatings, we understand that choosing the right epoxy coating for your facility is a significant decision. Our team of experts is dedicated to providing you with the information and support you need to make an informed choice. We pride ourselves on our attention to detail, quality of service, and our commitment to customer satisfaction.

With years of experience serving a wide range of industrial sectors, we are adept at identifying the perfect epoxy solution for any environment. By choosing us, you’re not just getting a service provider; you’re gaining a partner committed to enhancing the safety, efficiency, and aesthetics of your facility.

Conclusion

Choosing the right industrial epoxy floor coating is crucial for ensuring the durability, safety, and appearance of your facility. By taking into account your specific needs, environmental conditions, and working with professionals like Utah Epoxy Coatings, you can achieve optimal results that stand the test of time. Let us help you make the best decision for your floors. Reach out to us today by phone at 801-515-0892 or Request a Free Quote.