Floors carry the weight of everything—forklifts, foot traffic, dropped tools, muddy boots, and the grit that blows in off the Wasatch. If you’re in or around Salt Lake City, you know the drill: snow in the Garage in January, hot tires in July, and that fine dust all year long. That’s exactly why more homeowners and businesses are turning to epoxy coating when they need real, industrial-grade strength. It isn’t just about looks, though the shine is nice. It’s about making a floor that shrugs off work, wears well, and cleans up fast. You know what? When your floor works as hard as you do, everything else gets easier.

Contents

- 1 Why talk “industrial strength” for a home or business floor?

- 2 What epoxy actually is—without the headache

- 3 Epoxy vs. other Finishes: what actually holds up?

- 4 Performance pillars that matter day one—and day 1,001

- 5 Safety and style: not a trade-off

- 6 The Salt Lake City factor: snow, salt, sun, and swing seasons

- 7 Prep makes or breaks it (no, really)

- 8 What the Process looks like—step by step

- 9 Homeowners vs. businesses: tuned to what you need

- 10 Common questions we hear—answered straight

- 11 Costs and real value in the Salt Lake market

- 12 Why Utah Epoxy Coatings

- 13 Seasonal tips for Salt Lake floors

- 14 A quick local picture: SLC garages and work floors

- 15 Ready to fortify your floor?

Why talk “industrial strength” for a home or business floor?

Because the same stress that beats up a Warehouse floor shows up—just scaled down—in your garage or Shop. Salt, oil, hot tire pickup, dropped gear, pallet jacks, and spills. Even UV light sneaking in through a roll-up door can yellow cheap coatings. An industrial epoxy system is built to handle all of that. It’s a protective shell that bonds to concrete and gives it a tougher skin. The result: fewer stains, less dust, easier mopping, and a surface that looks finished, not tired.

For businesses, it’s more than curb appeal. A safer, brighter, slip-resistant floor improves workflow and morale. For homeowners, it’s simple—your garage feels like part of the house, not an afterthought.

What epoxy actually is—without the headache

Epoxy is a two-part system: a resin and a hardener. When they meet, they crosslink and cure into a dense, plastic-like surface that bonds to the concrete below. Not all epoxies are the same, though. Some are thick and tough; some are thinner and more DIY-friendly. The right match depends on how hard you plan to be on it.

Here’s the thing: the term “epoxy” covers a wide range. 100% solids epoxy builds real thickness in one coat. High-solids versions are strong too, just a little thinner. Water-based options are lighter-duty and often used as primers or in low-traffic spaces.

| Solid #ccc;”>Type | Typical Build | Best For |

|---|---|---|

| 100% Solids Epoxy | 20–60 mils in multiple coats | Warehouses, garages, shops needing heavy-duty protection |

| High-Solids Epoxy | 10–20 mils | Commercial spaces, basements, retail back rooms |

| Water-Based Epoxy | 3–10 mils | Light traffic, primer coats, budget refreshes |

Want extra speed and UV stability? Many systems use a polyaspartic or polyurethane topcoat over epoxy. It’s a tag-team: epoxy brings the muscle; the topcoat brings chemical resistance and better sunlight defense.

Epoxy vs. other Finishes: what actually holds up?

Let me explain with quick comparisons you can feel in real life:

- Concrete paint: Easy to apply; scuffs fast. Hot tires can lift it. Good for temporary sprucing, not workhorse spaces.

- Polished concrete: Beautiful and low maintenance. Still soaks up certain chemicals without guards. Can be slick when oily.

- Urethane cement: The tank. Handles thermal shock and heavy impact. Often used in food plants. Costs more but it’s a beast.

- Epoxy with polyaspartic topcoat: Versatile. Great balance of thickness, protection, and speed. Ideal for garages, shops, and warehouses.

If you want a balanced solution for both looks and strength, industrial epoxy floors with a durable topcoat check a lot of boxes—especially for Salt Lake City conditions.

Performance pillars that matter day one—and day 1,001

Numbers can feel dry, but they’re helpful. Abrasion resistance is often measured by the Taber test (ASTM D4060). Chemical resistance charts tell you what a floor can handle—think brake fluid, motor oil, bleach, and deicers. Compressive and tensile strength ratings show how the coating deals with point loads and impacts.

In plain terms, a good epoxy coating Salt Lake City installers recommend should:

- Fight abrasion: Sliding pallets and gritty dust won’t chew it up overnight.

- Resist chemicals: Spills wipe up without ghost stains.

- Handle impact: Tools drop. Life happens.

- Stay bonded: Prep is key; bonding is the backbone of the whole system.

- Protect against UV: Use a UV-stable topcoat near windows and big doors.

It’s not magic. It’s choosing the right system—and installing it right.

Safety and style: not a trade-off

Industrial strength doesn’t have to mean bland. You can build slip resistance with texture: Quartz, flakes, or micro-additives. You can also add safety yellow for forklift lanes or a contrasting color for edges and step-downs. Want that Showroom sheen? Flake broadcasts deliver it without being slick.

Color isn’t just mood. Light-gray and off-white floors bounce light, making the space feel brighter. That matters in a garage, a shop, and especially in a warehouse where workers need to see fast.

- Safety traction: Add grit or quartz to meet your slip needs.

- Line striping: Better traffic flow; fewer “oops” moments.

- Flakes and quartz: Hides wear, hides dust, and still looks sharp.

There’s even ESD epoxy for electronics areas. Most homes don’t need it, but it’s worth noting for labs and tech spaces along the Wasatch Front.

The Salt Lake City factor: snow, salt, sun, and swing seasons

Our climate throws curves. Winter brings deicing salt that chews bare concrete. Snowmelt puddles in garages, then dries to powder. Summer heat bakes in tire marks. And those freeze–thaw swings? They stress concrete, especially at joints and edges.

Moisture is the big sleeper issue. Many nearby neighborhoods have slabs that breathe water vapor. We test with ASTM F2170 in-situ RH or ASTM F1869 MVER. If the numbers run high, we use a moisture-mitigation epoxy primer that blocks vapor movement. This prevents bubbles, blisters, or peeling later.

Sunlight is another local quirk. Big garage doors mean big UV exposure. Epoxy can amber a bit; it’s normal. A UV-stable polyaspartic or polyurethane topcoat helps keep color truer, especially for light shades and flake systems.

Prep makes or breaks it (no, really)

Surface prep is half the battle. We’re talking dust-controlled diamond grinding or shot blasting to open the concrete pores and remove weak cream. Then we fix cracks, Chip out weak spots, and repair spalls. We fill expansion joints as needed—some we leave soft for movement, others get filled flush for a smooth roll.

Why the fuss? Epoxy sticks best to clean, profiled concrete. If a contractor skips prep, even the best product can fail. With the right profile, the coating bonds like glue and becomes one with the slab.

We also check for oil contamination. Garages see years of drips. Treating oil spots matters, because oil can block adhesion. A thorough clean, degrease, and grind changes everything.

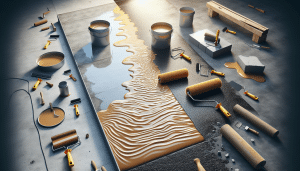

What the Process looks like—step by step

Here’s a straightforward picture of a typical garage epoxy or shop project in the Salt Lake Valley:

- 1. Inspect: We assess moisture, hardness, and damage. We talk through use: cars, forklifts, dogs, bikes, you name it.

- 2. Prep: Grind or blast, vacuum with HEPA, detail edges, and repair concrete.

- 3. Prime: Moisture-tolerant primer if needed; otherwise a bonding primer to lock things in.

- 4. Build coats: 100% solids epoxy for thickness and strength. Flakes or quartz if desired.

- 5. Topcoat: Polyaspartic or polyurethane for UV, abrasion, and chemical resistance.

- 6. Curing: Light foot traffic often within 12–24 hours; cars in 48–72 hours depending on the system and weather.

Fast projects are possible—especially with quick-cure systems—but we always balance speed with results. You want fast enough and done right.

Homeowners vs. businesses: tuned to what you need

Different spaces call for different builds. We help you choose what fits, not too much, not too little.

- Home garages: Flake epoxy with a UV-stable topcoat is the crowd favorite. Resists salt, hot tires, and weekend projects. Easy to mop.

- Basements: Low-odor options, usually high-solids epoxy with a satin urethane topcoat. Comfortable and bright.

- Shops and makerspaces: Thicker epoxy build; slip-resistant texture; neutral color that hides dust.

- Food and beverage: Quartz or urethane cement for sanitation, thermal shock, and frequent washdowns; USDA/FDA mindful.

- Warehouses and logistics: Durable epoxy with safety striping and high-gloss topcoat to boost lighting.

We also handle special needs: chemical-resistant epoxy for automotive bays, anti-slip for ramps, and anti-static for electronics and labs.

Common questions we hear—answered straight

Is epoxy slippery? Smooth epoxy can be slick when wet or oily. We add the right level of texture for your space. It’s a balance between cleanability and grip.

What about smell? Many commercial-grade epoxies are low VOC, and we use dust control and ventilation. Still, there’s a scent during install. It fades as it cures.

Will it yellow? Epoxy can amber in sun. That’s why we like a UV-stable topcoat. Choose flake or quartz blends that age gracefully.

Hot tires? A well-bonded system with a quality topcoat resists hot tire pickup. Prep is the key; cheap paint can’t handle it.

Cleaning? Dust mop or soft-bristle broom for daily. Neutral pH cleaner for mopping. Skip harsh acids. If you spill something gnarly, wipe it soon and you’re fine.

Costs and real value in the Salt Lake market

Budgets matter. For most residential garages in the area, professionally installed systems usually land somewhere in the middle hundreds to low thousands depending on size and build. Larger shops and warehouses vary, of course. As a ballpark, many projects fall in the range you’d expect for durable finishes—strong enough to last years, not months. The variables are prep, thickness, texture, moisture control, and topcoat choice.

Here’s how to think about it instead of chasing the lowest number:

- Longevity: A thicker, well-prepped system outlasts thin roll-on paint, hands down.

- Downtime: Faster-curing topcoats help you get back to work sooner.

- Maintenance: Easier cleaning saves time. Time is money, especially for businesses.

If you want specifics, we’re happy to measure, test, and give a clear, written Estimate. No vague ranges, no surprise add-ons.

Why Utah Epoxy Coatings

We’re local. We work all along the Wasatch Front, and we know how our climate treats floors. Our crews use commercial grinders with HEPA vacuums, proven materials, and a job plan that keeps things neat. We care about how the floor looks on day one and day 1,001.

- Real surface prep: Shot blasting or diamond grinding—no shortcuts.

- Moisture-aware installs: RH testing and moisture-blocking primers when needed.

- Top-tier products: Systems from names you know—Sherwin-Williams General Polymers, Dur-A-Flex, Sika, Tennant.

- Clean job sites: Dust control, taped edges, and tidy finishes you’ll notice.

- Warranty support: We stand behind our work with clear coverage.

We also help with practical choices: Colors that hide road salt, textures that don’t eat mops, and sheen levels that balance brightness with easy care.

Seasonal tips for Salt Lake floors

Quick seasonal notes—because timing helps:

- Winter installs: We can heat spaces to cure coatings, but plan for setup time. Snowmelt off cars will be the first test—these systems are built for it.

- Spring: Great for moisture testing; ground is wet, so readings are honest.

- Summer: Faster cures in warm temps. UV-stable topcoats shine—literally.

- Fall: Good window before early storms; perfect for shops gearing up for holiday rush.

Honestly, there’s no bad season—just different steps to get it right.

A quick local picture: SLC garages and work floors

Picture a Sugar House garage in February. Two cars roll in with slush and salt. With garage epoxy and a grippy topcoat, that mess stays on the surface and wipes right off. Or think of a light manufacturing space in West Valley. Pallet jacks run all day. A high-build epoxy with a satin urethane topcoat keeps the dust down and the traffic flowing. Same idea in a Park City home shop—just tweak the texture and color to match the space.

Different buildings, same goal: a floor you don’t have to baby.

Ready to fortify your floor?

If you’re planning a garage upgrade, a shop remodel, or a full warehouse refresh, we’ll help you choose the right epoxy coating in Salt Lake City—strong enough for real work, clean enough for everyday life. Give Utah Epoxy Coatings a call at 801-515-0892 and let’s talk about your space, your timeline, and your budget.

Prefer to start online? Click here to Request a Free Quote from Utah Epoxy Coatings”>Request a Free Quote. We’ll respond quickly, set up a site visit if needed, and lay out a clear plan that fits how you actually use your floor. No fluff—just a stronger surface that looks good and lasts.